Sunday, April 19, 2009

Descrete Multistage Light Sequencer Circuit

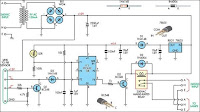

The drawing below illustrates a multistage light sequencer using

descrete parts and no integrated circuits. The idea is not new

and I hear a similar circuit was developed about 40 years ago

using germanium transistors. The idea is to connect the lights so

that as one turns off it causes the next to turn on, and so forth.

This is accomplished with a large capacitor between each stage

that charges when a stage turns off and supplies base current to

the next transistor, thus turning it on. Any number of stages can

be used and the drawing below illustrates 3 small Christmas lights

running at about 5 volts and 200mA. The circuit may need to be

manually started when power is applied. To start it, connect a

momentary short across any one of the capacitors and then

remove the short. You could use a manual push button to do this.

The circuit below uses a hex Schmitt Trigger inverter (74HC14)

60 Light Sequencer Circuit using a Matrix

The circuit below illustrates using a 10x10 matrix to sequence up

The LED circuit is drawn showing 25 LEDs and 10 transistors but

more

LED sequencer

The model 4017 integrated circuit is a CMOS counter with ten

Labels: led

Descrete Multistage Light Sequencer Circuit

The drawing below illustrates a multistage light sequencer using

descrete parts and no integrated circuits. The idea is not new

and I hear a similar circuit was developed about 40 years ago

using germanium transistors. The idea is to connect the lights so

that as one turns off it causes the next to turn on, and so forth.

This is accomplished with a large capacitor between each stage

that charges when a stage turns off and supplies base current to

the next transistor, thus turning it on. Any number of stages can

be used and the drawing below illustrates 3 small Christmas lights

running at about 5 volts and 200mA. The circuit may need to be

manually started when power is applied. To start it, connect a

momentary short across any one of the capacitors and then

remove the short. You could use a manual push button to do this.

The circuit below uses a hex Schmitt Trigger inverter (74HC14)

60 Light Sequencer Circuit using a Matrix

The circuit below illustrates using a 10x10 matrix to sequence up

The LED circuit is drawn showing 25 LEDs and 10 transistors but

more

LED sequencer

The model 4017 integrated circuit is a CMOS counter with ten

Labels: led

Saturday, April 18, 2009

Transistor LED flasher Circuit

This circuit has a lot going for it. For one thing, it only consists of two

transistors, two capacitors and four resistors. That also means it

consumes very little power. You can control the flash rate by changing

the size of the 100k resistors (100k makes for a pretty slow rate).

You can also control the duty cycle by using resistors of different

values on the two sides. The 470 ohm resistors control the current

through the LEDs. Normally you want to limit this to 20mA, but to

conserve battery power, you may need to limit it even further. You

can also connect several LEDs in series, instead of using only one

for each side. With red LEDs (1 per side) and the values shown,

the circuit draws about 11mA. more

more

Basic LED flasher circuit using NE555 timer IC

This circuit consumes more power, but it's advantage is when

more

more4 Parallel LEDs flashing circuit

Nominal flash rate: 1.3 Hz. Average IDRAIN e 2 mA

General Description

The LM3909 is a monolithic oscillator specifically designed

to flash Light Emitting Diodes. By using the timing capacitor

for voltage boost, it delivers pulses of 2 or more volts to the

LED while operating on a supply of 1.5V or less. The circuit

is inherently self-starting, and requires addition of only a battery

and capacitor to function as an LED flasher.

Packaged in an 8-lead plastic mini-DIP, the LM3909 will operate

over the extended consumer temperature range of

b25§C to a70§C. It has been optimized for low power drain

and operation from weak batteries so that continuous operation

life exceeds that expected from battery rating.

Application is made simple by inclusion of internal timing

resistors and an internal LED current limit resistor. As

shown in the first two application circuits, the timing resistors

supplied are optimized for nominal flashing rates and

minimum power drain at 1.5V and 3V.

12 LED Flasher

LED flasher in this circuit use 12 LED it can show 2 style .

more

1.5 volt dual LED flasher Circuit

This 1.5 volt led fasher runs more than a year on a single 'd" cell

Labels: led

Transistor LED flasher Circuit

This circuit has a lot going for it. For one thing, it only consists of two

transistors, two capacitors and four resistors. That also means it

consumes very little power. You can control the flash rate by changing

the size of the 100k resistors (100k makes for a pretty slow rate).

You can also control the duty cycle by using resistors of different

values on the two sides. The 470 ohm resistors control the current

through the LEDs. Normally you want to limit this to 20mA, but to

conserve battery power, you may need to limit it even further. You

can also connect several LEDs in series, instead of using only one

for each side. With red LEDs (1 per side) and the values shown,

the circuit draws about 11mA. more

more

Basic LED flasher circuit using NE555 timer IC

This circuit consumes more power, but it's advantage is when

more

more4 Parallel LEDs flashing circuit

Nominal flash rate: 1.3 Hz. Average IDRAIN e 2 mA

General Description

The LM3909 is a monolithic oscillator specifically designed

to flash Light Emitting Diodes. By using the timing capacitor

for voltage boost, it delivers pulses of 2 or more volts to the

LED while operating on a supply of 1.5V or less. The circuit

is inherently self-starting, and requires addition of only a battery

and capacitor to function as an LED flasher.

Packaged in an 8-lead plastic mini-DIP, the LM3909 will operate

over the extended consumer temperature range of

b25§C to a70§C. It has been optimized for low power drain

and operation from weak batteries so that continuous operation

life exceeds that expected from battery rating.

Application is made simple by inclusion of internal timing

resistors and an internal LED current limit resistor. As

shown in the first two application circuits, the timing resistors

supplied are optimized for nominal flashing rates and

minimum power drain at 1.5V and 3V.

12 LED Flasher

LED flasher in this circuit use 12 LED it can show 2 style .

more

1.5 volt dual LED flasher Circuit

This 1.5 volt led fasher runs more than a year on a single 'd" cell

Labels: led

Thursday, April 16, 2009

A simple automatic motion-detection Digital Camera Circuit

When the sensor detects movement in a room it will take a burst of

10 photos with the digital camera. Each photo is taken at 0.5sec

interval. After the 10 photos, the camera waits 3 seconds for further

movement and if it is detected, the process is repeated until 80

photos are taken.

The photos can then be downloaded to your PC (via the USB

connection on the board) for viewing.

The Directional Infrared Detector Module Circuit (DIRM)

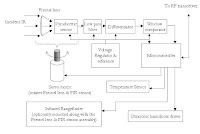

Figure shows a block diagram of the DIRM. A Fresnel lens

captures the incident IR and focuses it towards the

pyroelectric sensor increasing the sensitivity of the sensor

and improving its directional response. The resultant signal

passes through a low pass filter, which removes any high

frequency noise generated by mechanical vibration. The

output of the filter is then fed into a differentiator, which

produces an output voltage proportional to the rate of

change of the incident IR. The frequency response of this

differentiator is also rolled off at high frequencies, further

reducing the effects of undesired signals. The window

comparator produces a logic output whenever the rate of

change of incident IR exceeds a given set point.

An 8-bit PIC16F84 microcontroller processes the logic

signals and controls the rotating platform and reports

information to the team leader.

more

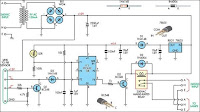

PIR DETECTOR USING ST7FLITE05 MICROCONTROLLER

A PIR detector can be made easily with ST7FLITE05 using the

circuit shown in Figure. The sensor interfacing circuit (shown on

the left side of the microcontroller in Figure ) can be divided

into the following modules:

1.Transistor circuit used as an amplifier.

2.Transistor biasing controlled through the microcontroller.

3. Software-controlled transistor output.

more pdf

Infrared, Alarm, and PIC Microcontroller

OBJECTIVES:

• Get familiar with an infrared emitter diode and receiver.

• Create an obstacle detector with an infrared emitter and receiver.

• Learn about PIC microcontroller and programming a PIC microcontroller.

• Write a PIC program and build the circuit of a household alarm system.

more pdf

Ultra-low Power Motion Detection using the MSP430F2013

A system capable of detecting motion using a dual element PIR

sensor is shown in Figure 1 using the MSP430F2013

microcontroller. Using the integrated 16-bit Sigma-Delta

analog-todigital converter and built-in front-end PGA (SD16_A),

the MSP430F2013 provides all the required elements for interfacing

to the PIR sensor in a small footprint. With integrated analog

and a 16MHz, 16-bit RISC CPU, the MSP430F2013 offer a great

deal of processing performance in a small package and at a low cost.

Labels: Infrared, Microcontroller, sensor

A simple automatic motion-detection Digital Camera Circuit

When the sensor detects movement in a room it will take a burst of

10 photos with the digital camera. Each photo is taken at 0.5sec

interval. After the 10 photos, the camera waits 3 seconds for further

movement and if it is detected, the process is repeated until 80

photos are taken.

The photos can then be downloaded to your PC (via the USB

connection on the board) for viewing.

The Directional Infrared Detector Module Circuit (DIRM)

Figure shows a block diagram of the DIRM. A Fresnel lens

captures the incident IR and focuses it towards the

pyroelectric sensor increasing the sensitivity of the sensor

and improving its directional response. The resultant signal

passes through a low pass filter, which removes any high

frequency noise generated by mechanical vibration. The

output of the filter is then fed into a differentiator, which

produces an output voltage proportional to the rate of

change of the incident IR. The frequency response of this

differentiator is also rolled off at high frequencies, further

reducing the effects of undesired signals. The window

comparator produces a logic output whenever the rate of

change of incident IR exceeds a given set point.

An 8-bit PIC16F84 microcontroller processes the logic

signals and controls the rotating platform and reports

information to the team leader.

more

PIR DETECTOR USING ST7FLITE05 MICROCONTROLLER

A PIR detector can be made easily with ST7FLITE05 using the

circuit shown in Figure. The sensor interfacing circuit (shown on

the left side of the microcontroller in Figure ) can be divided

into the following modules:

1.Transistor circuit used as an amplifier.

2.Transistor biasing controlled through the microcontroller.

3. Software-controlled transistor output.

more pdf

Infrared, Alarm, and PIC Microcontroller

OBJECTIVES:

• Get familiar with an infrared emitter diode and receiver.

• Create an obstacle detector with an infrared emitter and receiver.

• Learn about PIC microcontroller and programming a PIC microcontroller.

• Write a PIC program and build the circuit of a household alarm system.

more pdf

Ultra-low Power Motion Detection using the MSP430F2013

A system capable of detecting motion using a dual element PIR

sensor is shown in Figure 1 using the MSP430F2013

microcontroller. Using the integrated 16-bit Sigma-Delta

analog-todigital converter and built-in front-end PGA (SD16_A),

the MSP430F2013 provides all the required elements for interfacing

to the PIR sensor in a small footprint. With integrated analog

and a 16MHz, 16-bit RISC CPU, the MSP430F2013 offer a great

deal of processing performance in a small package and at a low cost.

Labels: Infrared, Microcontroller, sensor

Wednesday, April 15, 2009

Infrared motion detector Circuit

The pyroelectric sensor is made of a crystalline material that

generates a surface electric charge when exposed to heat in the

form of infrared radiation. When the amount of radiation striking

the crystal changes, the amount of charge also changes and

can then be measured with a sensitive FET device built into the

sensor. The sensor elements are sensitive to radiation over a wide

range so a filter window is added to the TO5 package to limit

detectable radiation to the 8 to 14mm range which is most sensitive

to human body radiation.

Typically, the FET source terminal pin 2 connects through a

pulldown resistor of about 100 K to ground and feeds into a two

stage amplifier having signal conditioning circuits. The amplifier

is typically bandwidth limited to below 10Hz to reject high

frequency noise and is followed by a window comparator that

responds to both the positive and negative transitions of the

sensor output signal. A well filtered power source of from 3 to

15 volts should be connected to the FET drain terminal pin 1

MX063 PIR SENSOR LIGHT Circuit

more

Application Schematic of Pyroelectric Infrared Motion

Sensors Circuit

Note: For best results the power supply should be very stable

at a constant +5V DC +/- .2V.This Schematic is offered for reference only without warranty

of any kind. Microsystem Technologies does not support user

designs or implementations that use this circuit

more

Automatic security lights Circuit

Combination PIR sensor and floodlight units are cheap but

rather inflexible if you want to locate the sensor and light in

different places. In my case, I wanted to detect movement

on the driveway and switch on the lights in the carport around

the corner. Yet another job for the ubiquitous PICAXE-08

microcontroller

The sensor interfaces to the PICAXE (IC1) on input 2 (pin 5).

This pin is pulled low via isolation diode D3 and the normally

open (NO) output of the sensor whenever movement is

detected. It can also be pulled low by transistor Q1, which acts

as a simple inverter for sensors with normally closed (NC) outputs.

more

Passive Infrared Motion Detector Circuit

This circuit was originally reverse -engineered from a motion

detecting yard light that I ripped apart. That's still probably the

best way to get the parts at a reasonable price, especially the

pyroelectric sensor and the absolutely necessary Fresnel lens.

The signal at pin 7 of the 324 is very interesting and fooling with

the filtering around the first amplification stage can make it even

more so. The LM324 is a wonderful little bug, and you will find

many uses for the window comparator if you look at it the same

way you would learn a new really useful knot. It all works on a

single 5 volt supply. The sensor is only sensitive to changes

across its surface, so don't expect a signal from a static object

even if it is hot. Yard lights are turning up at flea markets and yard

sales as people find themselves heads up every time the cat walks

past. This circuit is in a machine that sees people moving 40 feet

away.

Infrared motion detector Circuit

The pyroelectric sensor is made of a crystalline material that

generates a surface electric charge when exposed to heat in the

form of infrared radiation. When the amount of radiation striking

the crystal changes, the amount of charge also changes and

can then be measured with a sensitive FET device built into the

sensor. The sensor elements are sensitive to radiation over a wide

range so a filter window is added to the TO5 package to limit

detectable radiation to the 8 to 14mm range which is most sensitive

to human body radiation.

Typically, the FET source terminal pin 2 connects through a

pulldown resistor of about 100 K to ground and feeds into a two

stage amplifier having signal conditioning circuits. The amplifier

is typically bandwidth limited to below 10Hz to reject high

frequency noise and is followed by a window comparator that

responds to both the positive and negative transitions of the

sensor output signal. A well filtered power source of from 3 to

15 volts should be connected to the FET drain terminal pin 1

MX063 PIR SENSOR LIGHT Circuit

more

Application Schematic of Pyroelectric Infrared Motion

Sensors Circuit

Note: For best results the power supply should be very stable

at a constant +5V DC +/- .2V.This Schematic is offered for reference only without warranty

of any kind. Microsystem Technologies does not support user

designs or implementations that use this circuit

more

Automatic security lights Circuit

Combination PIR sensor and floodlight units are cheap but

rather inflexible if you want to locate the sensor and light in

different places. In my case, I wanted to detect movement

on the driveway and switch on the lights in the carport around

the corner. Yet another job for the ubiquitous PICAXE-08

microcontroller

The sensor interfaces to the PICAXE (IC1) on input 2 (pin 5).

This pin is pulled low via isolation diode D3 and the normally

open (NO) output of the sensor whenever movement is

detected. It can also be pulled low by transistor Q1, which acts

as a simple inverter for sensors with normally closed (NC) outputs.

more

Passive Infrared Motion Detector Circuit

This circuit was originally reverse -engineered from a motion

detecting yard light that I ripped apart. That's still probably the

best way to get the parts at a reasonable price, especially the

pyroelectric sensor and the absolutely necessary Fresnel lens.

The signal at pin 7 of the 324 is very interesting and fooling with

the filtering around the first amplification stage can make it even

more so. The LM324 is a wonderful little bug, and you will find

many uses for the window comparator if you look at it the same

way you would learn a new really useful knot. It all works on a

single 5 volt supply. The sensor is only sensitive to changes

across its surface, so don't expect a signal from a static object

even if it is hot. Yard lights are turning up at flea markets and yard

sales as people find themselves heads up every time the cat walks

past. This circuit is in a machine that sees people moving 40 feet

away.

Thursday, April 9, 2009

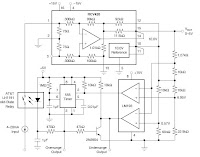

4-20mA Current Loop Receiver with Input Overload

Protection circuit

to convert a 4–20mA input signal into a 0–5V

output signal. As a monolithic circuit, it offers high

reliability at low cost. The circuit consists of a premium

grade operational amplifier, an on-chip precision

resistor network, and a precision 10V reference. The

RCV420 features 0.1% overall conversion accuracy,

86dB CMR, and ±40V common-mode input range.

FEATURES

-COMPLETE 4-20mA TO 0-5V CONVERSION

- INTERNAL SENSE RESISTORS

-PRECISION 10V REFERENCE

- BUILT-IN LEVEL-SHIFTING

- ±40V COMMON-MODE INPUT RANGE

- 0.1% OVERALL CONVERSION ACCURACY

- HIGH NOISE IMMUNITY: 86dB CMR

A current-sensing circuit derives its power from the

digital-signal recovery circuit

power supply of a 4-20mA loop. Also included is circuitry for recovering

a digital signal superimposed on that loop. U1 (a high-side current-

sense amplifier with comparator and reference) senses the loop current

in R1 as an 8-40mV voltage and amplifies it by 100, producing an

output-voltage range of 0.8V to 4V. That output (VOUT) can directly

drive external meters, strip-chart recorders, and A/D converter inputs.

More pdf

4-20mA Current Loop Receiver with Input Overload

Protection circuit

to convert a 4–20mA input signal into a 0–5V

output signal. As a monolithic circuit, it offers high

reliability at low cost. The circuit consists of a premium

grade operational amplifier, an on-chip precision

resistor network, and a precision 10V reference. The

RCV420 features 0.1% overall conversion accuracy,

86dB CMR, and ±40V common-mode input range.

FEATURES

-COMPLETE 4-20mA TO 0-5V CONVERSION

- INTERNAL SENSE RESISTORS

-PRECISION 10V REFERENCE

- BUILT-IN LEVEL-SHIFTING

- ±40V COMMON-MODE INPUT RANGE

- 0.1% OVERALL CONVERSION ACCURACY

- HIGH NOISE IMMUNITY: 86dB CMR

A current-sensing circuit derives its power from the

digital-signal recovery circuit

power supply of a 4-20mA loop. Also included is circuitry for recovering

a digital signal superimposed on that loop. U1 (a high-side current-

sense amplifier with comparator and reference) senses the loop current

in R1 as an 8-40mV voltage and amplifies it by 100, producing an

output-voltage range of 0.8V to 4V. That output (VOUT) can directly

drive external meters, strip-chart recorders, and A/D converter inputs.

More pdf

Wednesday, April 8, 2009

The XTR117 is a precision current output converter designed

to transmit analog 4-20mA signals over an industry-standard

current loop. It provides accurate current scaling and output

current limit functions.

XTR117 datasheet pdf

The PGA309 is a programmable analog signal conditioner

designed for bridge sensors. The analog signal path amplifies

the sensor signal and provides digital calibration for

zero, span, zero drift, span drift, and sensor linearization

errors with applied stress (pressure, strain, etc.). The calibration

is done via a One-Wire digital serial interface or

through a Two-Wire industry-standard connection. The

calibration parameters are stored in external nonvolatile

memory (typically SOT23-5) to eliminate manual trimming

and achieve long-term stability.

PGA309 datasheet pdf

The XTR117 is a precision current output converter designed

to transmit analog 4-20mA signals over an industry-standard

current loop. It provides accurate current scaling and output

current limit functions.

XTR117 datasheet pdf

The PGA309 is a programmable analog signal conditioner

designed for bridge sensors. The analog signal path amplifies

the sensor signal and provides digital calibration for

zero, span, zero drift, span drift, and sensor linearization

errors with applied stress (pressure, strain, etc.). The calibration

is done via a One-Wire digital serial interface or

through a Two-Wire industry-standard connection. The

calibration parameters are stored in external nonvolatile

memory (typically SOT23-5) to eliminate manual trimming

and achieve long-term stability.

PGA309 datasheet pdf

Tuesday, April 7, 2009

to transmit analog 4-20mA signals over an industry-standard

current loop. It provides accurate current scaling and output

current limit functions.

The on-chip voltage regulator (5V) can be used to power

external circuitry. A current return pin (IRET) senses any

current used in external circuitry to assure an accurate

control of the output current.

FEATURES

_ LOW QUIESCENT CURRENT: 130 uA

_ 5V REGULATOR FOR EXTERNAL CIRCUITS

_ LOW SPAN ERROR: 0.05%

_ LOW NONLINEARITY ERROR: 0.003%

_ WIDE-LOOP SUPPLY RANGE: 7.5V to 40V

_ MSOP-8 AND DFN-8 PACKAGES

0-5V To 4-20mA Current-Loop Transmitter Circuit

to–current converter specially designed for

analog signal transmission. The AM422 is

available in a 3– or 2–wire version, which allows

applications with flexible input voltage

ranges to be used for a standard output current.

Output current range and current offset level

are freely adjustable by external resistors. The

IC consists of three basic sections: an operational

amplifier input stage for single ended

input signals (0.5–4.5V, 0–10V, or other), a

programmable 4.5 to 10V reference for transducer

excitation, and a current output, freely

adjustable in a wide current range (4–20mA,

0–20mA, other). With the broad spectrum of

possible input signals the AM422 is a flexible

and multipurpose voltage–to–current converter

for single ended transducers or voltage transmission.

FEATURES

- Wide Supply Voltage Range: 6...35V

- Wide Operating Temperature Range: –40°C...+85°C

- Adjustable Voltage Reference:4.5 to 10V

- Operational Amplifier Input:0.5...4.5V, 0...5V, other

- Adjustable Offset Current

- Available as Three– (0/4...20mA) or Two–Wire Version (4...20mA)

- Adjustable Output Current Range

- Protection Against Reverse Polarity

- Protected Current Output

AM422 datasheet pdf

to transmit analog 4-20mA signals over an industry-standard

current loop. It provides accurate current scaling and output

current limit functions.

The on-chip voltage regulator (5V) can be used to power

external circuitry. A current return pin (IRET) senses any

current used in external circuitry to assure an accurate

control of the output current.

FEATURES

_ LOW QUIESCENT CURRENT: 130 uA

_ 5V REGULATOR FOR EXTERNAL CIRCUITS

_ LOW SPAN ERROR: 0.05%

_ LOW NONLINEARITY ERROR: 0.003%

_ WIDE-LOOP SUPPLY RANGE: 7.5V to 40V

_ MSOP-8 AND DFN-8 PACKAGES

0-5V To 4-20mA Current-Loop Transmitter Circuit

to–current converter specially designed for

analog signal transmission. The AM422 is

available in a 3– or 2–wire version, which allows

applications with flexible input voltage

ranges to be used for a standard output current.

Output current range and current offset level

are freely adjustable by external resistors. The

IC consists of three basic sections: an operational

amplifier input stage for single ended

input signals (0.5–4.5V, 0–10V, or other), a

programmable 4.5 to 10V reference for transducer

excitation, and a current output, freely

adjustable in a wide current range (4–20mA,

0–20mA, other). With the broad spectrum of

possible input signals the AM422 is a flexible

and multipurpose voltage–to–current converter

for single ended transducers or voltage transmission.

FEATURES

- Wide Supply Voltage Range: 6...35V

- Wide Operating Temperature Range: –40°C...+85°C

- Adjustable Voltage Reference:4.5 to 10V

- Operational Amplifier Input:0.5...4.5V, 0...5V, other

- Adjustable Offset Current

- Available as Three– (0/4...20mA) or Two–Wire Version (4...20mA)

- Adjustable Output Current Range

- Protection Against Reverse Polarity

- Protected Current Output

AM422 datasheet pdf