Tuesday, March 30, 2010

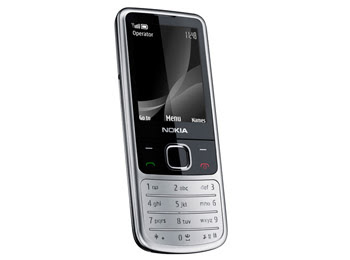

NOKIA 6303i classic REVIEW

The 6303i classic now comes stomaching enhanced battery talents, enabling you to make up to 8 hours of calls. It’s also capable of letting you listen to around 30 hours of music via its built-in music player and FM radio, and will sit tight for over three weeks on standby.

Extending its rack of communication tools, the 6303i supports instant messaging for enhanced social savviness. It also features a 3.2-megapixel camera with dual LED flash, geared up for easily sharing your sharp snaps online.

We touched on the topic of refinement a few weeks ago and it’s place in mobile innovation and development cycle, and the 6303i classic is certainly another example of this to sit alongside the likes of the similarly honed E72. What do you think?

The 6303i classic begins shipping in selected territories this quarter.

The 6303i uses the S40 6th edition user interface. The interface is simple and intuitive. There is not much change in the UI over its predecessor 6303. The home screen has got slight make over, which features usual status reading like signal & battery status, caller ID. When the keypad is locked, if you press end key, it shows time and date. The menu system also got some renovation. The new mode displays a single icon at a time. The interface is boring as the icons lack the animations. Since it lacks multitasking, you can’t minimize java apps like Opera browser and do other tasks.

The Nokia 6303i Classic offers connectivity in the form of GPRS and EDGE, both of which are class 32. Micro-USB and blue tooth are also included as standard and offer additional connectivity options. The handset comes with an internal memory capacity of 55 MB, with a 2 GB card included in most packages, whilst for further memory capacity the existing microSD card slot and relevant cards can be used to increase capacity up to 16 GB.

The handset offers an impressive 2.2 inch TFT display screen which offers impressive levels of colour variance by virtue of its 16 million colour options. The handset offers the alternative of either ring or vibration alerts as well as the ability to utilise existing MP3 files as ringtones. The phone also comes with a speakerphone which provides effective hands free communication in addition to a 3.5 mm audio jack which offers the option of personal listening, should this be desired or required.

The Classic Nokia 6303i is an impressive handset, styled in a popular style with a range of functionality that makes it a viable option for many.

SPECIFICATIONS

General

2G Network GSM 900 / 1800 / 1900

Announced 2010, February

Status Available. Released 2010, March

Size

Dimensions 108.8 x 46.2 x 11.7 mm, 57 cc

Weight 96 g

Display

Type TFT, 16M colors

Size 240 x 320 pixels, 2.2 inches

Sound

Alert types Vibration, MP3 ringtones

Speakerphone Yes

- 3.5 mm audio jack

Memory

Phonebook 2000 entries, Photocall

Call records 20 dialed, 20 received, 20 missed calls

Internal 55 MB

Card slot microSD, up to 8GB, 2GB included, buy memory

Data

GPRS Class 32

EDGE Class 32

3G No

WLAN No

Bluetooth Yes, v2.1 with A2DP

Infrared port No

USB Yes, microUSB v2.0

Camera

Primary 3.15 MP, 2048x1536 pixels, autofocus, dual LED flash

Video Yes, QVGA@8fps; QCIF@15fps

Secondary No

Features

Messaging SMS, MMS, Email, IM

Browser WAP 2.0/xHTML, HTML

Radio Stereo FM radio with RDS

Games 8 + Downloadable

Colors Steel, Matt Black, Chestnut, Illuvial pink, White on Silver, Khaki on Gold

GPS No

Java Yes, MIDP 2.1

- Nokia Maps 2.0

- H.263/H.264 player

- MP3/WAV/eAAC+/WMA player

- Organizer

- Flash Lite 3.0

- Voice memo/dial

- T9

Labels: NOKIA 6303i classic

Friday, March 26, 2010

Nokia 2330 Classic REVIEW

Nokia 2330 Classic REVIEWThe Nokia 2330 Classic is an entry level Nokia phone with a classic design. With smooth rounded edges and a stylish flat keypad, the 2330 Classic features a VGA digital camera which can also capture video. Share your photos with friends using the 2330's built in Bluetooth or MMS and Email capabilities. The Nokia 2330 also features a built in FM radio so you can tune in to the latest hits and supports MP3 ringtones so you can choose your favourite track and set it as your ringtone.Presented to us in two colour choices, the Nokia 2330 classic will be available in black with the silver keypad trim, as pictured, or Deep Red. Weighing in at a polite 90 grams and with dimensions of 13.8mm x 46mm x 107mm, this handset fits neatly into most pockets. Offering a 1.8” TFT display with 65k colours and 160 x 128 pixels, the integrated VGA digital camera can be used with ease to create images and videos. These can be stored easily in the 32 Mbytes of memory. For those who like to listen to their favourite FM radio station whenever they can, the dedicated FM Radio key allows easy listening supported by the internal antenna. Once fully charged a talk time of 4.8 hrs and standby time of 540 hrs can be expected. Also offering all the usual suspects of SMS and MMS, Bluetooth® technology and a built in web browser, the user will be able to use the Nokia Xpress audio messaging service to share audio messages with compatible contacts. The Hands Free and Conference call features, audio recording and a good selection of ring tone formats also help to round off this elegant edition to the Nokia Classics range.

In summary, the Nokia 2330 Classic is an elegantly crafted handset which delivers all the minimum aspects we have come to expect in our mobile phones with the quality we have come to expect from Nokia. It is a lovely little phone, ideal for all ages, particularly those who don’t want to be blinded by science but want up to date basic applications. Calling, texting, gaming, web browsing, taking pictures, making videos and listening to music, all from a classy little handset

THE SPECIFICATIONS

General

Status Available

Introduced May 2009

Announced November 2008

Network (2G) GSM 900 / GSM 1800

Form factor Block

Antenna type Internal

SAR Value 0.980 W/Kg

Size

Weight 80.0 g (with battery)

Dimensions 107.0 x 46.0 x 13.0 mm

Display

Type Graphical

Coloured Yes, TFT, 65K colors

Size 1.80 inch

Resolution 128 x 160 pixels

- 5-way navigation key

Memory

Numbers in phone 1000

Received calls 20

Outgoing calls 20

Lost calls 20

Ringtones

Polyphonic ringtones Yes

Ringtone profiles Yes

- MP3

Networking

GPRS Yes

Bluetooth Yes

WAP Yes

Browser Yes, WAP 2.0/xHTML

Email client Yes

Features

Vibration Yes

SMS Send / Receive

MMS Send / Receive

Camera Builtin, VGA, 640x480 pixels

Java Yes, MIDP 2.0

Games Yes

Clock Yes

Alarm Yes

Calculator Yes

Calendar Yes

Voice memo Yes

T9 Yes

Handsfree Yes

FM Radio Yes

Labels: Nokia Classic Series

Thursday, March 25, 2010

Nokia has first ensured that the new 5630 XpressMusic ticks the musical boxes. Comes with Music enabled in selected countries, it’s ready to soak up to 3,000 songs into its slender shell via a 4GB microSD memory card that comes in the box. Likewise, its tuneful talents extend to the ’say and play’ feature (first debuted on the 5320 XpressMusic last year), letting you speak the name of an artist of track to automatically play it. Plus, the Nokia 5630 comes loaded with a 3.5mm headphone connector, stereo Bluetooth, FM stereo and Internet radio to wrap up its music credentials. Now here comes the twist…

Alongside those core talents sit some unusual but welcome suspects on the features front. For starters it’s a full blown S60 device with fast HSDPA connectivity, meaning it’s primed to be loaded with apps and able to exploit many of the best Internet services out there, such as widgets (a la the 5800 and upcoming N97), Ovi Share and Nokia Messaging.

Similarly, it throws N-Gage gaming into the mix – only the second time Nokia’s premium gaming platform has been available on a non Nseries device (the 6210 just got there first). However, at just 12mm slim and weighing only 83g, this makes the Nokia 5630 XpressMusic the slimmest and lightest N-Gage gaming device to date.

Another smart addition is the home screen, which features a new Contacts Bar that has a definite widget feel to it – smartly animated, you can scroll through icons for up to 20 contacts and interact with them directly from the home screen.

The 5630 XpressMusic from Nokia comes with a complete N-Gage experience with an N-Gage shortcut on the homescreen. N-Gage offers an entire catalogue of mobile games from leading game publishers, a multiplayer game feature, and the ability to track progress, as well as add friends to play games against. In addition, the Nokia 5630 cell phone comes with a full focus 3.2 megapixel camera with flash function. Pictures or videos can be captured and shared via a favorite online community, such as Share on Ovi, Flickr, or Facebook.

General

2G Network GSM 850 / 900 / 1800 / 1900

3G Network HSDPA 2100 / 900

Announced 2009, February

Status Available. Released 2009, June

Size

Dimensions 112 x 46 x 12 mm

Weight 83 g

Display

Type TFT, 16M colors

Size 240 x 320 pixels, 2.2 inches

Sound

Alert types Vibration; Downloadable polyphonic, MP3 ringtones

Speakerphone Yes

- 3.5 mm audio jack

- Dedicated music keys

Memory

Phonebook Practically unlimited entries and fields, Photocall

Call records Detailed, max 30 days

Internal 60 MB storage, 128 MB RAM

Card slot microSD, up to 16GB, 4GB included, buy memory

Data

GPRS Class 32

EDGE Class 32

3G HSDPA, 10.2 Mbps; HSUPA, 2 Mbps

WLAN Wi-Fi 802.11 b/g, UPnP technology

Bluetooth Yes, v2.0 with A2DP

Infrared port No

USB Yes, v2.0 microUSB

Camera

Primary 3.15 MP, 2048x1536 pixels, enhanced fixed focus, LED flash

Video Yes

Secondary VGA videocall camera

Features

OS Symbian OS, S60 rel. 3.2

CPU ARM 11 600 MHz processor

Messaging SMS, MMS, Email

Browser WAP 2.0/xHTML

Radio Stereo FM radio with RDS

Games Yes, N-gage + downloadable

Colors Red on black, Blue on grey, Chrome on grey

GPS No

Java Yes, MIDP 2.1

- WMV/RV/MP4/3GP video player

- MP3/WMA/WAV/RA/AAC/M4A music player

- Voice memo

- T9

Labels: Nokia XpressMusic SERIES

Monday, March 22, 2010

Labels: Heat Sinks

Labels: Heat Sinks

Saturday, March 20, 2010

Labels: Heat Sinks

Labels: Heat Sinks

Thursday, March 18, 2010

Labels: Heat Sinks

Labels: Heat Sinks

Tuesday, March 16, 2010

NOKIA C5 SPECIFICATIONS

Brand / Type

Brand Nokia

Type C5

Form factor Candybar

Color Black, White

Network

Phone Network EDGE, GPRS, GSM, HSDPA (3G), HSUPA

Service 850, 900, 1800, 1900, 2100

Connectivity

Bluetooth v2.1 with A2DP

Infrared No

Wi-Fi (WLAN) No

USB MicroUSB v2.0

Fax / Data Yes

Display

Main display Color TFT

Color display 16.000.000 colors

Dimensions 2.2 in.

Resolution 240 x 320 pixels

External display No

Memory

Internal memory 50MB

External memory 16GB

Memory slots Yes

Storage types MicroSD, MicroSDHC

Basic

Battery Standard battery, Li-Ion 860 mAh (BL-5CT)

Standby time 670 hours

Talk time 12 hours

Calling

Vibrate alert Yes

Photo ID Yes

Ringtones MP3

Camera

Camera Yes

Megapixels 3.15 megapixels

Maximum photo resolution 2048x1536 pixels

Digital zoom Yesx

Optical zoom No

Auto focus Yes

Flash Yes

Recording video Yes

Second (front) camera Yes

Messaging

SMS Yes

MMS Yes

T9 text function Yes

E-mail Yes

Internet browsing Yes

Entertainment

FM radio Yes

Java Yes

Audio player eAAC, MP3, WAV

Video player H263, H264, MP4, WMV

Features

Add ringtones Yes

Organiser Document viewer (Word, Excel, PowerPoint, PDF), Organiser, Voice memo

Video call Yes

Other features Symbian OS 9.3, 2GB included, S60 rel. 3.2, Speakerphone, 3.5 mm audio jack, Downloadable games, GPS with A-GPS support, Nokia Maps

Format

Weight 3.2 oz.

Dimensions (H x W x D) 4.4x1.8x0.5 in.

Labels: NOKIA

Labels: Heat Sinks, HEAT TRANSFER

Labels: Heat Sinks, HEAT TRANSFER

Sunday, March 14, 2010

Labels: Heat Sinks, HEAT TRANSFER

Labels: Heat Sinks, HEAT TRANSFER

Friday, March 12, 2010

Thermal Management Using Heat Sinks and Effects of Heat on Electronic Circuits and Devices

0 comments Posted by blogger at 3:53 AMLabels: Heat Sinks

Thermal Management Using Heat Sinks and Effects of Heat on Electronic Circuits and Devices

0 comments Posted by blogger at 3:53 AMLabels: Heat Sinks

Tuesday, March 2, 2010

Based amplifier IC's offer many advantages including high efficiency, high gain, low standby current, low component count, small size and, of course, low cost. It is little wonder that audio amp IC's have replaced most discrete transistors in consumer electronic devices. While many experimenters have stayed away from these little black Mysteries, I am going to uncover some of their secrets and demonstrate how easy they are to use

Rangkaian Amplifier IC LM380

Amplifier IC LM380 comes in two flavors; LM380 and LM380-8 with output powers of 700 milli-watts and 2 watts respectively. A schematic drawing below depicts the 8th and LM380-LM380.

Labels: Home Amplifier, LM Amplifier

Rangkaian Amplifier V-Mosfet 100 Watt

The use of diodes D2 until D5 in combination with the resistances R17-19, they protect the gates of transistors v-fet from exceeds the voltage ± 14V and it creates perforation in very thin layer SiO2, that is used as insulation in the gate. This way of protection is common in all the amplifiers that use these transistors. The total gain of amplifier is 32.6, regulated from the R18, R6 and R8, in the negative feedback. Also is used enough the use of local feedback for stabilisation of operation under all the conditions. Because the transistors v-fet have positive factor of temperature, with result with the increase of temperature is increased also their resistance. This increase has as result the reduction of current that via the transistor, hence also his power. The use of separated supply in the stages of drive and exit, ensures stability and reject of distortion of intermodulation.

Series of VMOS FET POWER [ 2SK134 or 2SK135 ] [ 2SJ49 or 2SJ50 ], they are that, more above transistor they are not produced more by the Toshiba and are enough difficult they are found henceforth. They can be replaced with [ 2SK1530 in the place of 2SK135 ] and [ 2SJ201 in the place of 2SJ50 ]. The new transistors are in plastic case ΤΟ-3Ρ and no TO-3, bear in bigger supply of operation and have positive factor of temperature. This mean that with the increase of temperature, is increased and the current that is gone through from through the transistor. The new transistors him I have still not tryed and me it would interest to learn if somebody him used also with which results.

List Componet

R1=27Kohm

R2-11=4.7Kohm

R3-4=5.6Kohm

R5=47Kohm

R6=1Kohm

R7-10-21=22Kohm

R8=12ohm

R9=1Mohm

R12=33ohm

R13-20=82ohm

R14=33ohm

R15=2.7Kohm

R16=270ohm

R17-19=680ohm

R18=33Kohm

R22-23=0.33ohm 5W

R24=8.2ohm

R25=10ohm 1W

TR1=470ohm trimmer

TR2=4.7Kohm trimmer

C1=1uF 63V mkt

C2=1nF 100V*

C3=100uF 16V

C4=100nF 100V*

C5-7=22uF 16V

C6=4.7pF ceramic

C8=47uF 16V

C9=1nF 100V*

C10-11=100uF 100V

C12-14=100nF 250V mkt

C13=150nF 100V mkt

C15=100uF 35V

D1=12V 0.5W Zener

D2.....5=8.2V 1W Zener

L1=20 turns 0.6mm on R25

Q1-2=BC 547

Q3=2N5460 fet

Q4-5=MPSA93

Q6-8-11=BC182

Q7-10=MPSA43

Q9=BC212

Q12=2SK134 or 2SK135

Q13=2SJ49 or 2SJ50

Labels: Home Amplifier, Mosfet Amplifier